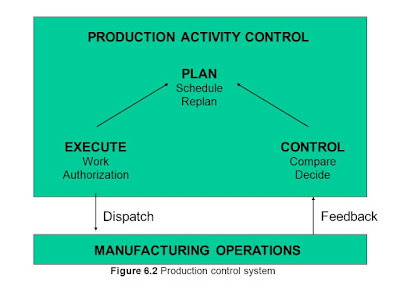

Three Major Functions

Planning

The flow of work through each of the

work centers must be planned to meet delivery dates. So, the production must

first, ensure that the required materials, tooling, personnel, and information

are available to manufacture the components when needed. Second, schedule

starts and completion dates for each shop order at each work center so the

scheduled completion dates of the order can be met. This will involve the

planner in developing a load profile.

Implementation

After the plans are made, the PAC

must make the plans into an action by give the shop floor what must be done. The

PAC usually give an instruction by issuing a shop order such as; gather the

information needed by the shop floor to make the product. Then, release orders

to the shop floor as authorized by the material requirements plan. This is

called dispatching.

Control

Once plans are made and shop orders released, the

process must be monitored to learn what is actually happening. The PAC wiil do,

rank the shop orders in desired priority sequence by work center and establish

a dispatch list based on this information. Then, monitor and control wok-in-process,

lead times, and work center queues.

Credit by : Zulaikha

Credit by : Zulaikha

Comments

Q: Anonymous said…

i wanted to ask, why do we need control in PAC?

A: We need control in PAC because we need to control if the production have any delay, damage or etc.